ACETO

Checkout securely with:

CDC Anti-Clog Condensation Pan Treatment

IMPROVED CHEMICAL FORMULATION:

FUNCTIONAL DESIGN

Place ANTI-CLOG under cooling coils in middle of pan length. It goes to work immediately upon contact with water!

The Anti-Clog is designed and approved only for use in drain pans of Air Conditioning Systems and Refrigeration Systems.

HERE'S WHAT THE CITY OF NEW YORK DEPARTMENT OF HEALTH SAYS ABOUT EPA REGISTERED BIOCIDE FEEDERS:

"Fan-coil units and air handlers should be equipped with an EPA registered biocide feeder or treated with an EPA registered biocide formulated for this purpose. These are designed to inhibit bacterial growth, prevent clogging of the condensate drain system and prevent odors. Such treatment is considered to be consistent with good engineering practices". (From a report issued by Commissioner R. Ferrer, M.D.)

WHY is the Anti-Clog # 1 needed

1. CONDENSATION

Cooling equipment produces cold air by passing warm air over cooling coils. This cooling action causes condensate (water droplets) to form and drip off the cooling coils, similar to the droplets formed on the glass of a cool drink on a hot day!

Have you ever seen water dripping out of a window air conditioner? This is a common example of condensation.

2. DRAINAGE

In large commercial cooling equipment, condensate cannot be allowed to drip out onto passersby or other objects. Therefore, the condensate must be collected in a drain pan inside the unit. When enough droplets collect, the condensate begins flowing to a drain hole. IT IS HERE IN THE DRAIN PAN THAT POTENTIAL TROUBLE BEGINS!

3. BACTERIA

Bacteria, naturally present in water including condensate, produce "SLIME" as a waste product.

ACCUMULATIONS OF SLIME CAN:

WHERE is the Anti-Clog # 1 needed?

WHEREVER AIR CONDITIONING/REFRIGERATION IS USED!!!

WHEN is the best time to install the Anti-Clog # 1?

FOR OPTIMAL PERFORMANCE:

Initial placement: Install the ANTI-CLOG #1 during preseason maintenance programs prior to system start-up.

Follow-up maintenance: Replace the ANTI-CLOG #1 every 3 months for the duration of the cooling season.

Following this recommended usage program will protect buildings from:

HOW does the Anti-Clog # 1 work?

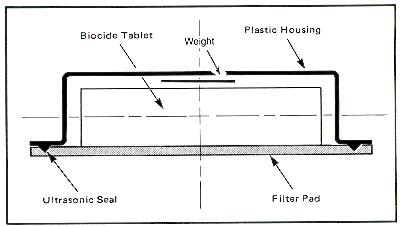

The ANTI-CLOG #1 is a biocide (quaternary ammonium) tablet enclosed in a plastic housing. Ultrasonically sealed to the housing is a white filter pad. Water is absorbed by the filter pad and "wicked" to the tablet. The release of powerful biocide is initiated as the water begins dissolving the tablet. The filter pad controls the release of biocide resulting in a 3-month service life in even the hottest and most humid climates!

The ANTI-CLOG #1 works either horizontally or vertically at angles up to 60°, without compromising performance.

WHY is the Anti-Clog # 1 a superior product?

ANTI-CLOG #1: INEXPENSIVE HEALTH PROTECTION AND PREVENTATIVE MAINTENANCE!

In laboratory tests the Anti-Clog formulation has been shown to inactivate pure cultures of Disease-Causing Bacteria. The ability of this formulation to control the growth of or inactivate bacteria in air conditioning condensate drain pans exposed to organic material and other microbial contamination has not been documented.

A direct relationship between the presence of this bacteria and the potential for human disease has not yet been proven.

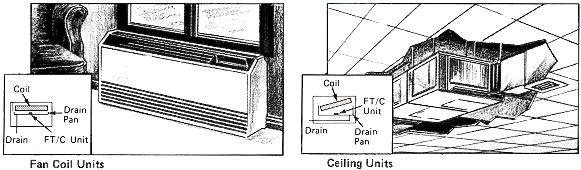

ANTI-CLOG # 1 PLACEMENT:

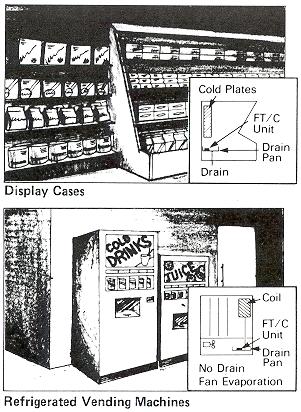

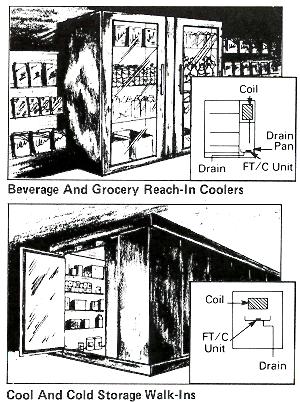

FT/C: FOR EQUIPMENT UP TO 5 TONS.

AT/C: FOR EQUIPMENT OVER 5 AND UP TO 15 TONS. NOTE: FOR LARGER EQUIPMENT USE MULTIPLE UNITS.

IMPORTANT:

DO NOT USE in Humidifiers, Humidifier Sections in Air Conditioning Systems or Evaporative Coolers IF Heat Lamps Sit Directly Over or Near Drain Pan Where the Anti-Clog #1 Has Been Installed.

REFRIGERATION:

AIR CONDITIONING:

SPECIFICATIONS:

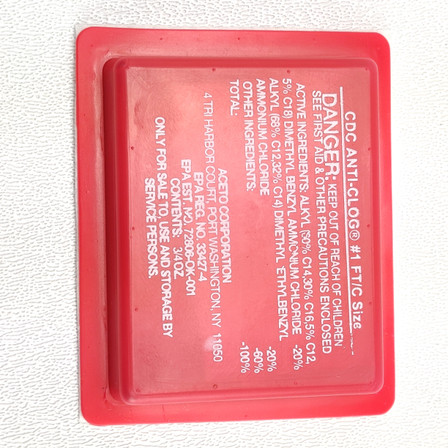

CHEMICAL SPECIFICATIONS:

Active ingredients:

Alkyl (60% C14, 30% C16, 5% C12, 5% C18) Dimethyl Benzyl Ammonium Chloride - 20%

Alkyl (68% C12, 32% C14) Dimethyl Ethylbenzy] Ammonium Chloride - 20%

Inert Ingredients: 60%

MECHANICAL SPECIFICATIONS:

FT/C - 2 3/4" long x 2 1/4" wide x 1/2" high, contents 3/4 oz.

AT/C - 3 5/8" long x 2 3/4" wide x 7/8" high, contents 2 1/8 oz.

NOTE: Not for use in applications exceeding 150°F.