Walchem

Checkout securely with:

The EWN Series electronic metering pumps offer superior high speed dosing capability with more standard features. The flexibility of the EWN pump enable it be integrated into virtually any chemical feed application using a universal-voltage, digital controller with an expanded set of control features. Superb valve performance and advanced solenoid engineering combine to make a highly precise pump for the most demanding applications.

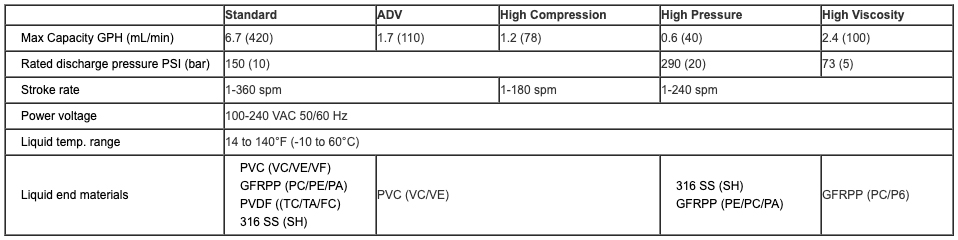

EWN Series pumps have outputs to 6.7 GPH (25.2 L/h) and a maximum pressure of 290 PSI (20 bar). The high speed of operation results in high resolution chemical feed and long service life. Quiet and compact, the EWN pumps prime in seconds and hold prime reliably.

Two controller options provide various features, outputs and flexible pump control including scalable Analog control, Digital Input with Multiply and Divide capability, Batch control, external Stop, AUX and Interlock inputs, analog and alarm outputs as well as simple speed & stoke length control. Display of can be adjusted between flow rate units, % speed or SPM for easy-to-read output and enables quick adjustment. The controller is universal voltage so it can be used anywhere in the world.