Neptune

Checkout securely with:

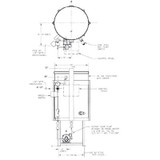

Gly-pak Industrial Glycol Feed System

The Gly-pak glycol feed system is used to automatically feed a glycol mixture into closed loop piping used in HVAC chill water and hot water recirculation systems. The glycol feeder is activated when it's internal pressure sensor indicates a low pressure condition. A gear pump feeds the glycol solution into the attached system piping until normal pressure is achieved. Optionally dry contacts will be activated on pump start or low level to indicate an alarm condition exists. We suggest that the dry contacts be connected the building management system and alert personnel that the glycol feed system is active indicating there may be an abnormal leak in the system. Several models are available and can be customized to fit any application.

Standard Features:

Optional Features:

Model Configuration Options:

Model Numbering Example:

"GP55-E4-1/HM-AL-DC"

(Base)(Size)(Pump)(Pressure)/(Options)

Base Model:

"GP" Standard Glycol Feed Package

"GX" Wall Mount Glycol Feed Package (No Tank)

"GDW" Double Wall Glycol Feed Package

"DGP" Digital Glycol Fed Package

Size: (Gallons)

15, 30, 55, 100 Standard Wall (custom sizes available)

18, 35, 65, 120, 160, 220 Double Wall Sizes

Pump:

"E4" 1/3HP, 1.3GPM at 100PSI gear pump

"E5" 1/2HP, 3.0GPM at 100PSI gear pump

Pressure Settings: (Range)

1, 10-45 cut-in, 20-50 cut-out, 10-30 pressure differential

2, 40-80 cut-in, 65-100 cut-out, 20-40 pressure differential

3, 3-10 cut-in, 9-30 cut-out, 6-20 pressure differential

Options:

“D” Dual Pumps with dual manifolds, controls and indicators

“H” High Temp tank and manifolds

“HM” High temperature manifold

“AL” 95 decibel audible alarm and silence switch

“DC” Remote dry contact on low level or special order on pump start

“MX” Batch mixer, mount bracket and control switch

“HL” High level indicator

“UV” Ultraviolet prohibitive black polyethylene tank and cover

“TEFC” Totally enclosed Fan Cooled pump motor

“MTR/STR” Motor starter, 20 AMP

“AUX” Auxiliary pump adder (Standby)

“ALT” Alternating pump adder

“EMS05” Dry contact control box for up to 5 sensing points

"DTS" Digital Touch Screen Controller with Datalogging

"NET" Ethernet port

"420" 4-20mA Output on Pressure

Note: All options are not available on all models. Please consult us for product specification, price and availability.