What are the Important Parts of a Reverse Osmosis Equipment?

Posted by David Cannon on 14th Aug 2019

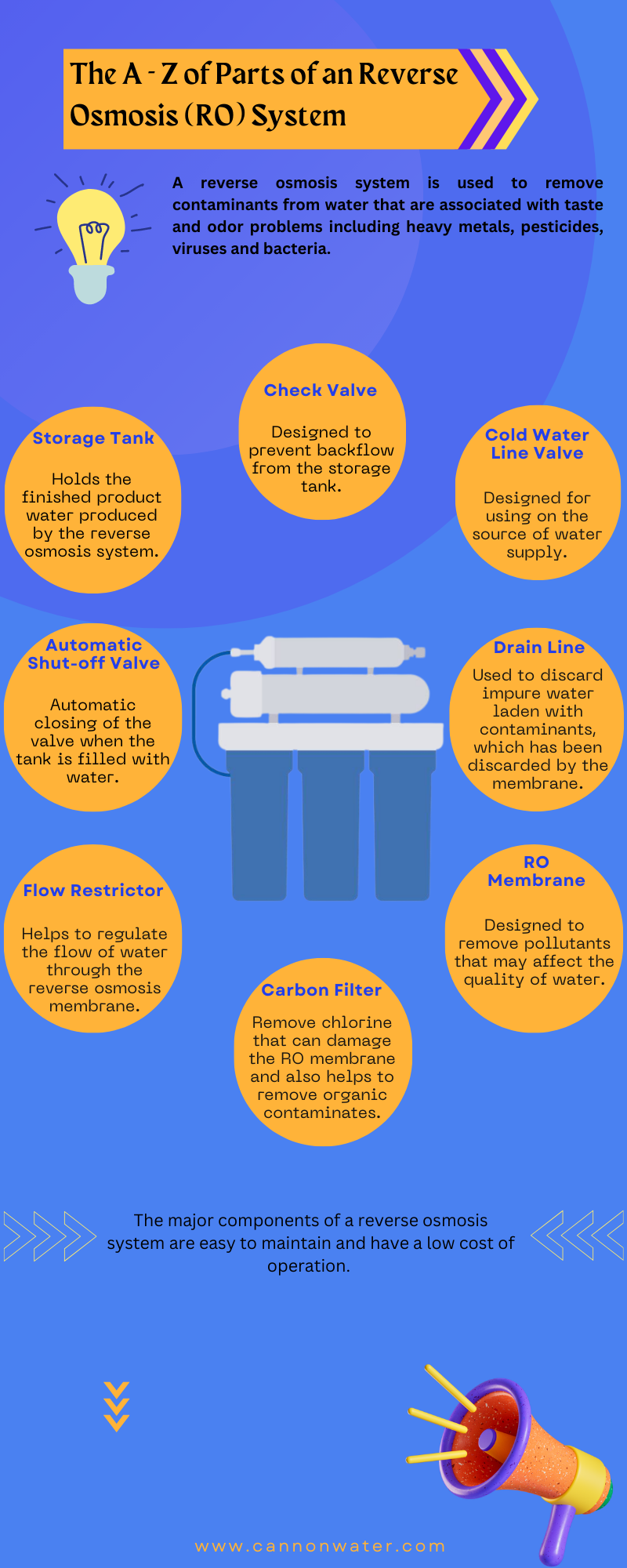

Reverse osmosis water filtration systems are widely used in industrial, commercial, and residential areas to filter drinking water. Reverse osmosis equipment is used to remove contaminants that are associated with taste and odor problems to include heavy metals, pesticides, viruses and bacteria. The major components of a reverse osmosis system are easy to maintain and have a low cost of operation.

Basic Parts of an RO System Discussed in Detail

Understanding the function of each of these parts will help you understand how the system works.

Infographic: The A to Z Parts of an Reverse Osmosis System

- Storage Tank: The storage tank holds the finished product water produced by the reverse osmosis system. It can hold almost two to four gallons of water on average, more if a larger tank is required. Most storage tanks are available in a standard size, 15 inches tall and 12 inches wide, and feature an air-filled bladder that creates water pressure. The water remains pressurized when tank is full. The tank is lined with a non-corrosive liner and are made from metal or all plastic.

- Automatic Shut-off Valve (SOV): It aids, automatic closing of the valve when the tank is filled with water. It means, SOV alters water flow to the membrane, and also stops water from flowing to the drain. The SOV will open when the pressure of the tank lowers.

- Check Valve: This one way check valve is designed to prevent backflow from the storage tank, which may otherwise impair the membrane. The check valve located the outlet end of the membrane cartridge.

- Cold Water Line Valve: As the name suggests, this valve is designed for using on the source of water supply. It comprises a tube, which is fixed to the pre-filter of the RO system. The tube is found on the inlet of the pre-filter. It serves as the water source for the reverse osmosis system.

- Drain Line: This line is used to discard impure water laden with contaminants, which has been discarded by the membrane. The drain line is routed to plumbing under a sink and is connected using a saddle clamp connection.

- Flow Restrictor: It helps to regulate the flow of water through the reverse osmosis membrane. The flow helps maintain the necessary flow rate required to acquire quality filtration. The performance of this entirely depends on the filtration capacity of the reverse osmosis membrane. This reverse osmosis part also helps in maintaining pressure on the membrane’s entry side. Without this component, excess water will flow into the drain.

- Pre-filter: The water is first filtered by a pre-filter, which helps removes dirt and sediments.

- Carbon Filter: The carbon block filter will remove chlorine that can damage the RO membrane and also helps to remove organic contaminates that cause taste and odor issues.

- Post-filter: The post filter will help to polish the product water and continue to neutralize the taste and odor elements in water. A carbon filter is used for the purpose of filtration.

- RO Faucet: Post-filtered water enters into the faucet. Most RO systems are equipped with non-gap faucets. This faucet is lined with a plastic material to prevent corrosion due to the aggressive nature of RO water.

- RO Membrane: This is the main part of an RO system. It is designed to remove pollutants that may affect the quality of water. The water that comes out of the membrane is directed to the storage tank. Many types of semipermeable membranes are available; however, the one with thin-film composite polyamide is most commonly used in RO filters. In recent years, large-diameter membranes, improved low-pressure membranes, and non-fouling membranes have gained popularity. Utilizing these membranes help improve the quality of water filtration and reduce costs of chemical additives.

Although simple in design a reverse osmosis system requires some technical knowledge to correctly select the best equipment and features for the job. These systems are available in different configurations and can be ordered based on the amount of RO water needed for any application. Cannon Water Technology has the experience and expertise to help you find the best RO system for the application. Cannon Water Technology offers reverse osmosis equipment from various brands and can help you find a system that will be both cost effective and efficient to utilize.

|

|

Watts 20" Coconut Carbon Block filter cartridges |

|

|

|

DOW FILMTEC Membrane RO Filter Element |

|

|

|

DOW FILMTEC BW30-365 Membrane RO Filter Element |