Vector Industries

Checkout securely with:

The Vector FA-900AL-TC chemical by-pass filter feeder is used to introduce chemicals into closed system recirculation loops and to filter out suspended particles like rust nodules, metal flakes, dirt and debris in the circulating water. This system is used for water treatment applications like chill water recirculation loops, hot water circulating systems, cooling tower chemical feeders and water treatment systems alike. The purpose for this chemical filter feeder is to make adding chemicals to the closed loop and for removing particulates in the water treatment system easy and efficient. The bag style filter is very durable and can be rinsed out and reused for many years. The Vector chemical shot feeders are constructed of the highest quality steel and are epoxy coated to ensure a very long life. This filtration bypass feeder has a unique buttress threaded cap allowing it to achieve a 300 PSI rating which is the highest pressure rating found in in chemical by-pass feeders on the market today.

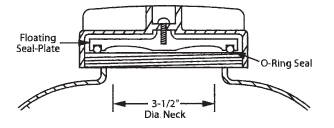

Cross dissection of the 1/4 buttress threaded cap assembly with self alining floating seal plate between the neck of feeder and cap.

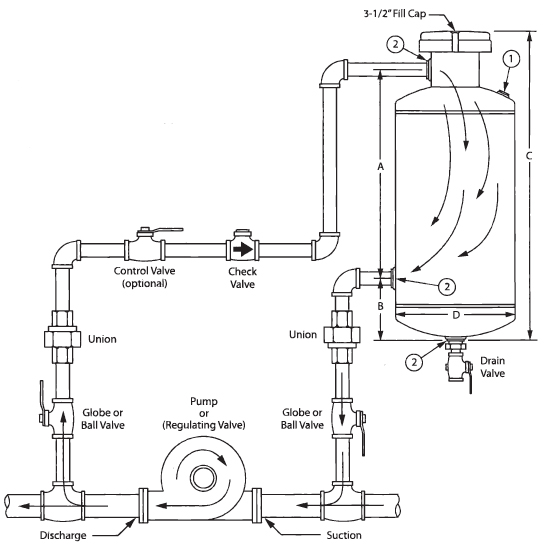

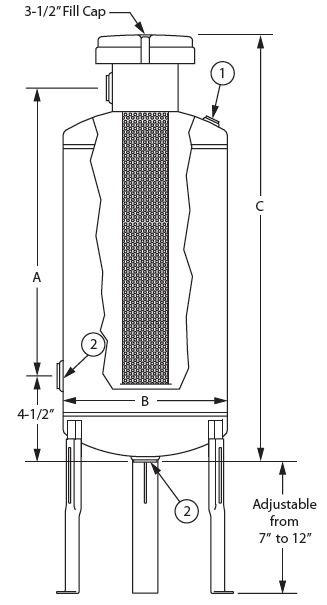

1 = 1/4" Vent Valve Fitting

2 = 1" Inlet/Outlet Fittings.

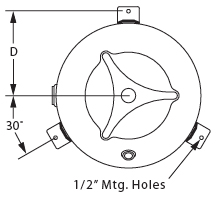

| Model | Approx. Capacity | A | B | C | D | Shipping Weight |

| FA-900AL-TC | 5 Gallons | 20" | 4.5" | 28.5" | 10" | 44 Lbs |

The Vector FA-900AL-TC chemical bypass filter feeders are designed for maximum operating specifications of 300 PSI (13.8 BAR), 200 F (93 C)

When selecting pipe valves and fittings ensure that they meet the working pressure of the system being treated.

Install chemical bypass feeder in accordance with one of the following configurations

Feeder chemicals like liquids, pucks, briquettes, granular or powdered chemicals - Close inlet and outlet valve and drain tank by opening bottom drain and air release petcock valve. After system is depressurized, open cap and fill with desired amount of chemical. Replace cap, close drain and begin filling tank by opening the inlet valve at bottom of feeder with air vent petcock valve open until feeder is topped off and all air has been purged from the tank. Close petcock valve and open outlet valve on feeder allowing chemical to flow into system.