SUB CATEGORIES OF Flow Control Systems

At Cannon Water Technology, we offer range of flow control devices such as flow sensors, flow switches, tank alarms, drum alarms, and more to avoid overflow, and more from trusted brands such as Carlon Meters, Walchem, Stenner, and others, ensuring reliability, quality, and efficiency for our clients’ needs. All of these devices cater to various aspects of flow control, level measurement, and so on. Also, they are handy and easy to use, and are designed to withstand corrosive and harsh environments.

Working Principle of Flow Control Devices

To regulate the flow of liquid, control valves get signals from connected sensors, based on which they maintain the required temperature, pressure, flow rate, and so on. This function of the valve is crucial as the flow velocity may change the temperature, pressure, and other parameters. The operational mechanics of modern liquid flow control systems begins with sensor technology that continuously measures flow characteristics including velocity, pressure, and volume.

These sensors transmit data to control units that process information against predetermined parameters, triggering valve adjustments when deviations occur. Actuators respond to electronic signals by modifying valve positions, either restricting or expanding flow passages to maintain target conditions. Feedback loops ensure constant system awareness, creating self-correcting mechanisms that respond to changing demands.

Advanced fluid flow control system architectures incorporate multiple measurement points throughout piping networks, enabling differential analysis and enhanced accuracy. Pressure compensators account for upstream and downstream variations, while temperature sensors provide additional data layers for comprehensive process monitoring. This multi-parameter approach ensures stability across fluctuating operational conditions, maintaining consistent output regardless of external variables.

Significance of Fluid Flow Control Systems in Industrial Applications

Fluid flow control devices offer a range of features that significantly improve process control and efficiency. Here’s why they are significant for industries that rely on fluid flow management.

- Precision Regulation: Advanced sensors and control algorithms maintain flow rates within tight tolerances, ensuring consistent process conditions. This precision eliminates variations that compromise product quality, reduce yield, or create downstream processing challenges that affect final output specifications.

- Energy Conservation: Optimized flow management reduces pump workloads and minimizes unnecessary fluid movement throughout systems. Lower energy consumption translates directly to reduced utility expenses, while decreased equipment strain extends component lifecycles and reduces replacement frequency across operational infrastructure.

- Safety Enhancement: Automatic shutdown capabilities activate when sensors detect dangerous conditions such as excessive pressure or flow anomalies. These protective features prevent equipment failures, contain potential hazards, and protect personnel from exposure to dangerous situations involving high-pressure fluids or hazardous materials.

- Scalability: Modular system architectures accommodate facility expansions and process modifications without complete infrastructure replacement. Additional sensors, valves, and control points integrate seamlessly with existing installations, protecting capital investments while supporting business growth and changing production requirements.

- Compliance Support: Accurate flow measurement and comprehensive data logging satisfy regulatory documentation requirements across industries. Automated record-keeping simplifies audits, demonstrates due diligence, and provides verifiable evidence of operational practices that meet environmental and safety standards.

How to Install Fluid Flow Control Systems?

Installing a fluid flow control system requires careful planning and precise execution to ensure optimal performance. Proper installation can enhance the longevity and efficiency of the system, while poor installation may result in operational failures or safety concerns.

- Site Assessment: Conduct thorough evaluations of installation locations, examining pipe dimensions, material compatibility, and spatial constraints. Understanding environmental conditions including temperature ranges, vibration sources, and accessibility requirements ensures appropriate equipment selection and mounting strategies that support reliable operation.

- Equipment Selection: Match liquid flow control system components to specific process requirements, considering fluid characteristics, flow ranges, and accuracy needs. Proper sizing prevents performance limitations, while the right material selection ensures chemical compatibility and prevents corrosion that could compromise measurement accuracy or cause premature failures.

- Pipe Preparation: Ensure clean, debris-free piping before installing sensors and control valves to prevent contamination that affects accuracy. Proper pipe runs with adequate straight sections upstream and downstream from flow meters eliminate turbulence that distorts measurements and creates unpredictable flow profiles.

- Calibration Procedures: Perform initial calibration using reference standards that establish baseline accuracy for all measurement instruments. Document calibration values and maintain records that support future troubleshooting, provide audit trails, and establish performance benchmarks for periodic verification activities throughout operational lifecycles.

- Electrical Integration: Connect sensors and actuators to control systems following manufacturer specifications regarding wire gauges, shielding, and grounding. Proper electrical installation prevents signal interference, protects against voltage fluctuations, and ensures reliable communication between distributed system components across facility infrastructure.

Maintenance Tips for Flow Control Devices

Routine maintenance of flow control devices ensures reliable performance and longevity. Regular checks and proper servicing prevent issues that could lead to system failures or inefficiency.

- Regular Inspections: Schedule periodic visual examinations of all flow control device components, checking for leaks, corrosion, and physical damage. Early detection of deteriorating conditions enables timely interventions that prevent catastrophic failures, reduce repair costs, and maintain operational continuity throughout production schedules.

- Sensor Cleaning: Contamination from process fluids gradually degrades performance, making regular cleaning essential for maintaining calibration standards and ensuring reliable data collection across monitoring networks. Remove accumulated deposits from sensor surfaces that interfere with measurement accuracy and create reading errors.

- Calibration Verification: Conduct periodic accuracy checks against reference standards to confirm sensors maintain specified tolerances over time.

- Valve Maintenance: Inspect and service control valves, replacing worn seals, cleaning actuators, and verifying smooth operation throughout stroke ranges. Mechanical wear compromises response times, and hence routine valve maintenance is critical for preserving system performance and preventing leakage that causes material losses.

- Record Maintenance: Historical records reveal patterns that inform replacement scheduling, support warranty claims, and provide valuable data for optimizing maintenance strategies and predicting future requirements.

What is Fluid Control Mechanism?

This is a mechanism in fluid dynamics that controls, operates, and manages flow control of fluids of varied consistencies. This is done in industrial processes which involve the flow and transfer of a given fluid from one node to other one or multiple nodes. The fluid may be thin, viscous, semi-solid, particulate, slurry, or any other consistency. The fluid control system has an indicator that issues an alert regarding any issue such as overflow, leakage, and more. It also sends messages to the system once the receiving end receives the fluid.

Beneficial Features and Types of Flow Control Systems

There are several benefits of each flow control device we offer. Here are some of the types of flow control systems we offer, along with their benefits.

- We offer flow control switches which help prevent dry run of motors. They are compact devices which can be easily connected to a pumping system. Once a preset flow cycle is completed, the switch trips on its own and the pumping system turns off. We offer several types and configurations of flow switches.

- Our selection also features a flow sensor, which helps sense and control the flow of fluid. Some of the switches we offer act as water flow sensors, and hence can measure the speed of flowing liquid. The other types of sensors include flowmeters which are designed to handle high pressures and temperatures.

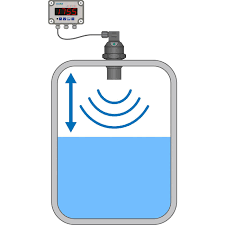

- We offer a variety of liquid level controller devices. These include drum alarms and flow alarms among others. These are installed in tanks for fluid level control. A liquid level controlling device comprises a controller, measuring device, and a tank. These controllers monitor the level of fluid based on preprogrammed settings.

- Made of sturdy plastic such as polypropylene, our drum alarms are designed for monitoring fluid level in drums by connecting them to a feed line and installing inside the drum. These devices are battery-controlled that can work for prolonged periods. They have a rugged design suitable for corrosive, moist, and overall harsh environments.

- Our tank alarms come with light indicator and beeper sound which function in case of fluid overflow or dry run. They are battery powered and easy to install. They are weatherproof and comply to NEMA 4X construction standards. They come with Lithium batteries and AC adapters.

Industry-Specific Applications of Flow Control Technology

Diverse sectors depend on precise liquid flow control system technology to meet unique operational requirements and regulatory obligations. Understanding industry contexts reveals how flow control technology enables critical processes.

- Water Treatment: Municipal and industrial facilities rely on accurate chemical dosing, filtration rates, and distribution management for safe water delivery. Precise flow regulation ensures proper disinfection levels, optimizes treatment chemical usage, and maintains consistent water quality that meets health standards.

- Chemical Processing: Chemical processing and formulating operations require exact reagent ratios, reaction temperature control, and batch consistency for product specifications. Flow accuracy directly impacts yield rates, product purity, and process safety, making sophisticated control systems essential for competitive chemical production.

- Pharmaceutical Manufacturing: Strict quality requirements in this sector necessitate validated flow measurement systems with complete traceability and documentation for regulatory submissions. Precision control ensures active ingredient concentrations, supports batch consistency, and provides audit trails that demonstrate manufacturing control throughout production processes.

- HVAC Systems: Commercial buildings utilize flow control for heating and cooling distribution, optimizing comfort while minimizing energy consumption. Balanced flow throughout building infrastructure ensures uniform temperature distribution, prevents equipment strain, and reduces operational costs through efficient resource utilization.

- Industrial Manufacturing: Production facilities across sectors require cooling water management, hydraulic system control, and process fluid regulation. Reliable fluid flow control system technology supports continuous operations, protects equipment from damage, and maintains the stable conditions necessary for consistent manufacturing output.

Our flow control systems and devices work at various levels and are applicable in several industrial processes. At Cannon Water Technology, we have an excellent team that understands your requirements and helps you select the right device. While we manufacture our own devices, as source them from other reputed players as well, such as Flowline, Gizmo, and more. In case you are interested in any of our flow control systems and devices, you can reach us via phone or email. Also, we can offer you a quote once we analyze your requirements.

FAQs

- How does ambient temperature affect flow control device performance and accuracy?

Extreme temperatures can impact sensor accuracy and valve operation, requiring temperature-compensated devices or environmental protection. We specify equipment rated for your installation environment to ensure reliable performance.

- How do flow control systems handle sudden demand spikes or supply interruptions?

Advanced systems incorporate surge protection, buffer capacity management, and intelligent response algorithms that maintain stability during disturbances. Proper system design anticipates operational variables and incorporates appropriate protective measures.

- Can flow control systems operate effectively with viscous or particulate-laden fluids?

Specialized sensors and valve designs accommodate challenging fluid properties including high viscosity, suspended solids, and corrosive chemicals. One needs to select proper equipment to meet specific requirements or fluid characteristics.

- How often should you calibrate flow instruments from professional calibration services?

Calibration frequency depends on application criticality, regulatory requirements, and observed drift patterns, typically ranging from quarterly to annually. We recommend establishing schedules based on your specific operational and compliance needs.