How to Remove Sand from Well Water Using Different Techniques

Posted by David Cannon on 29th Jul 2021

A clean and well-maintained well in a backyard is a dream for many house and commercial property owners. This is because, a well helps them achieve water efficiency and reduces their dependency on other public water resources. Although it may sound easy, regular well maintenance can be difficult due to various challenges involved. The presence of sand and sediments is one of the common concerns for most well owners. They use various filtration techniques individually or in combination to get rid of sand and sediments. Using centrifugal separators is one of the most effective methods of removing sand from water. Is that all? No, there are other methods, too, which have been successfully used by well owners for removing sand and sediments for several years. This post introduces you to these techniques and more.

How to Remove Sand from Well Water Using Centrifugal Separators and Other Proven Techniques

How to remove sand from water? This has been a concern for most well owners for several years now. They have been using several techniques for the filtration of sand and sediments. The following are a few popular ones.

- Centrifugal Sand Separators: These equipment uses centrifugal action to filter sand and sediments from water. The following pointers will help you understand it better.

- The water from the well is directly ensued through the separator, which pushes sand, large particles, sediments, and debris to the separator wall.

- These sediments and particles are further pushed downward to the spin trap plate, which is located in the holding chamber.

- Clean water is made to pass through the vortex locator and is driven back to the plumbing system.

This technique has gained immense popularity in recent years due to the following reasons:

- They possess no filter media, screens, chemicals, or moving parts, because it works on the concept of centrifugal force.

- As there are no moving parts, so regular maintenance is not required. It can be rightly said that no regular repairs are needed as well, because no parts get damaged easily.

- The periodic opening of the purging valve is recommended to flush out sand, sediments, and other solids.

- This purging can be easily done using automatic or manual flush valves.

- These systems are proven to achieve an effective removal of almost 98% of 200 mesh-sized particles.

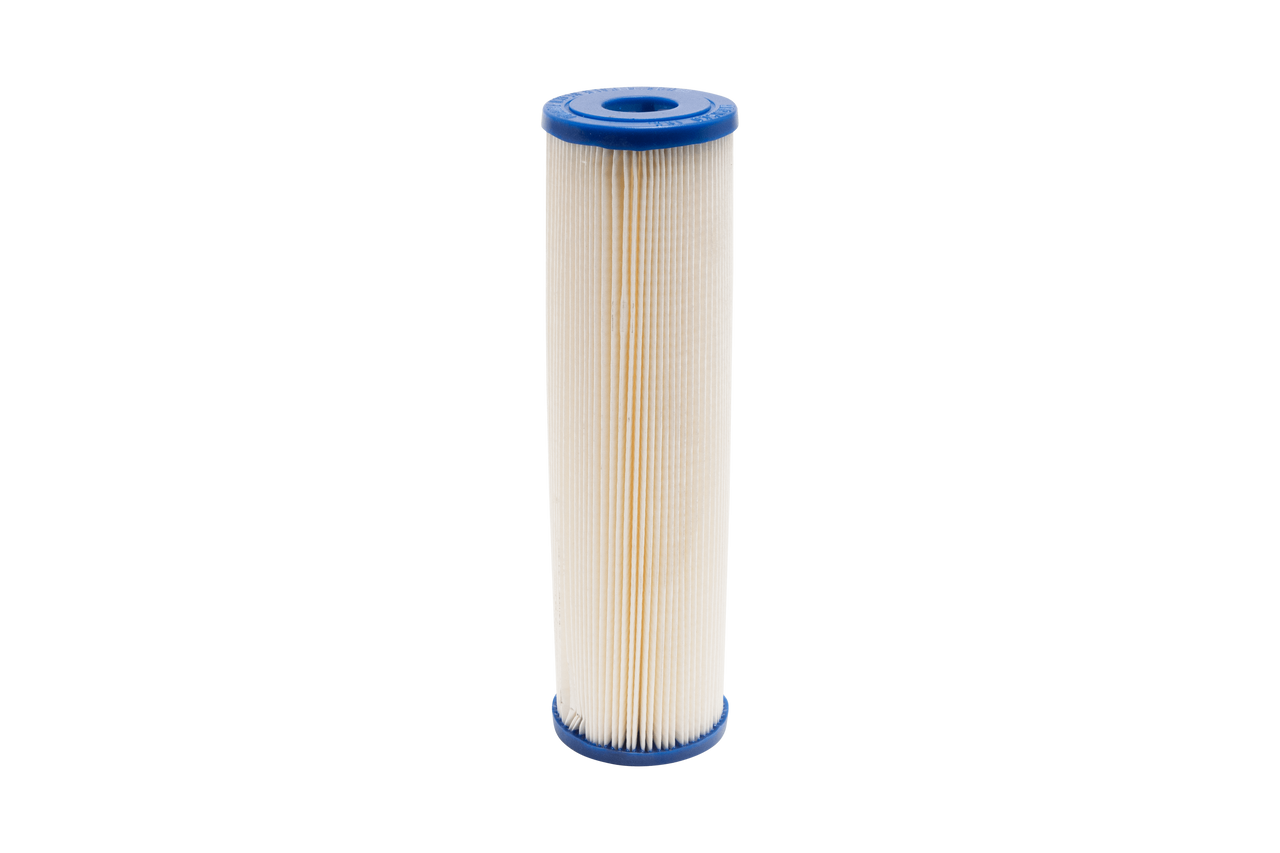

- Sediment Filter Cartridge Systems: These filtration systems are equipped with filter cartridges, which can remove silt, sand, clay, and sand grains from water. It is often established as the first line of filtration in many commercial wells. The following pointers will help you understand the functioning of these filters.

- They follow a technique of mechanical filtration, which blocks particles from entering your water systems.

- The water is forced through a filter, which has thick walls. It becomes tight when water nears the core.

- The filter captures all small and fine particles along its way.

- Some filters use a depth gradient to filter the particles that are suspended in water, whereas others may use large surface areas to capture the debris of different forms.

- These filters are known to remove turbidity from water, which is caused by heavy suspended solids.

- These systems are often used in conjunction of ultraviolet and reverse osmosis filtration for effective results.

- Sediment Backwash Filtration Systems: These filtration systems feature filter media, backwash control valve, tank, and bypass valve. The backwash filtration systems can retain sediments, rust, or dust in the water. These systems are not known to restrict the flow, unlike regular filtration systems.

If you are planning to install these solutions in your well for effective sand and sediment removal, it is important to source them from trusted suppliers. There are several suppliers who deal with these equipment, however, not all may carry the solutions described here. This is where Cannon Water Technologies can help. The company has been providing effective solutions for residential, commercial, and industrial water treatment applications for several years now. To know more, all you have to do is get in touch with the experts at the company and they will provide you tailored solutions based on your requirements.