Checkout securely with:

The principal use of the REGAL Gas Chlorinator is to chlorinate water, wastewater and industrial process water with gas chlorine. The simple, efficient design has made REGAL Gas Chlorinators the industry standard. Built with heavy duty corrosion resistant parts, REGAL Chlorinators provide safe, long-lasting service. The REGAL Automatic Switchover Gas Chlorinator is a totally vacuum-operated system which is designed to automatically switch the chlorine feed from an empty cylinder to a full cylinder. It is also designed to provide system-backup. Should a problem develop with either vacuum regulator, chlorination can be continued. The chlorinators are of the vacuum-operated solution-feed type, designed for mounting directly on a chlorine cylinder valve, a wall manifold or REGAL Model TAY-200 ton container adaptor. The switchovers are self-actuating, eliminating the need for a separate switchover module.

A separate gas flow meter and rate control valve panel may be located wherever it is most convenient for the operator and connected between the vacuum regulator junction at the pressure relief (vent) valve, and the ejector, by means of safe vacuum tubing. The ejector assembly contains a back flow check valve. Chlorine gas flow rate is regulated by a spring-opposed diaphragm regulator which is also the automatic safety shut-off valve. Should vacuum be interrupted for any reason anywhere in the system the safety shut-off/inlet valve immediately closes, shutting off the chlorine supply from the cylinder. A pressure relief valve designed to “vent” the system also provides a central interconnection point for the vacuum tubing.

FEATURES

CAPACITIES

Dual scale metering tubes are provided with the following maximum capacities. Minimum feed rate is 1/20th of maximum.

Model 216 - 4, 10, 25, 50 or 100 PPD (75, 200, 500, 900 or 2000 gms/hr)

Model 226 - 250 PPD (5kg/hr)

Model 256 - 500 PPD (10 kg/hr)

FLOW RATE ADJUSTMENT

Manually adjustable by means of a flow rate control valve located at the top of the flow meter. Flow rate is then regulated by a special spring opposed diaphragm operated valve. The system is automatic. It will go off and on as the ejector water is turned off and on and will return to the pre-set flow rate.

EJECTOR REQUIREMENTS

The standard ejector is designed to withstand static back pressure up to 200 psig (14.1 kg/cm2). The amount of water required to operate the ejector depends upon the chlorine feed rate. Generally, the higher the chlorine flow, the greater the water flow is required.

OPERATION

The chlorinators are clamped onto the chlorine cylinder valves. The ejector assembly is normally attached to the solution diffuser at the point of injection. A vacuum line is connected from each cylinder unit to the wall-mounted, pressure-relief (vent) valve, and a single vacuum line connects the outlet of the connector to a wall-mounted, flow meter/rate valve panel. The ejector is connected to the rate valve panel with a single vacuum line.

Water, under pressure, is forced through the ejector nozzle which creates a strong vacuum in the ejector body. This pulls gas into the ejector through a special back-flow check valve and then into the nozzle outlet. The gas mixes with the ejector water and is discharged through the diffuser into the water being treated. The ejector vacuum is transmitted through the vacuum line to the rate valve and the flow meter; then through the connector on the pressure-relief (vent) valve and on to the back of the operating chlorinator diaphragm.

With sufficient vacuum, the diaphragm moves backward, opening the spring-loaded inlet regulating valve to allow chlorine to enter from the cylinder. The chlorine passes through the chlorinator, the pressure-relief (vent) valve, rate indicating meter/flow rate adjusting valve to the ejector.

When the operating cylinder starts to run out, the vacuum starts to build up in the system causing the diaphragm of the chlorinator on “stand-by” to be drawn back, overcoming a detent mechanism and opening the safety/inlet valve. This allows chlorine gas to be withdrawn from the “stand-by” cylinder to satisfy the increased system vacuum and the vacuum falls back to the operating level. The original supply cylinder also continues to feed until it is empty, virtually assuring that there will be no interruption of chlorination and that full use will be made of all available chlorine. This also reduces the

SPECIFICATIONS

The chlorination system shall be a vacuum-operated, solution-feed type and shall automatically switch the chlorine supply from an empty cylinder to a full cylinder. It shall be REGAL Model 200 Series manufactured by Chlorinators Incorporated, Stuart, Florida with capacities ranging from 4 to 500 lbs/24 hours (PPD). The vacuum-operated, automatic switchover chlorinator shall consist of the following components: Two (2) automatic switchover vacuum regulators for mounting directly on chlorine gas cylinder valves, one (1) pressurerelief (vent) valve, one (1) chlorine gas flow meter panel with rate valve and one (1) ejector/ check valve assembly. The vacuum regulators shall mount directly onto the cylinder valve or directly onto the REGAL TAY-200 ton container adaptor by means of a positive yoke type clamp having an integral tightening screw with slide bar handle. All metallic bolts shall mate with metallic threaded nuts or inserts. Plastic mating threads for metallic bolts shall not be acceptable. Each chlorinator vacuum regulator shall have its own diaphragm, safety-shutoff/inlet valve and switchover detent mechanism, thereby, allowing chlorination to continue should it become necessary to remove either vacuum regulator from service for cleaning or servicing. Switchover detent mechanism shall be made of corrosion-resistant materials and shall not require any field adjustment.

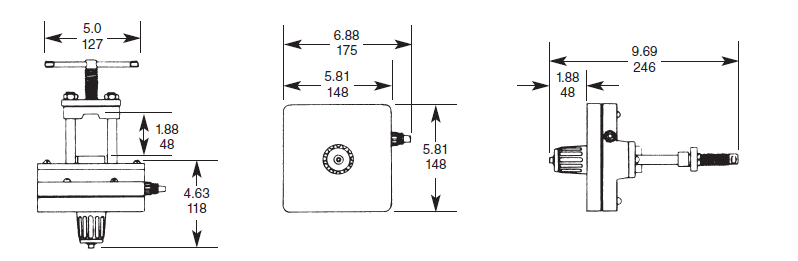

VACUUM REGULATOR DIMENSIONS

Automatic Switchover Vacuum Regulator Cylinder or Manifold Mounted*

UP TO 500 PPD (10 Kg/Hr)

Contents: Model 216

2 each Model A-816 Vacuum Regulators with 3/8" Vent and Vacuum Fittings

1 each Model A-255 Remote Meter Panel with 3/8" Vacuum Fittings (For Wall Mounting)

1 each Model A-300V1 Pressure Relief (Vent) Valve with 3/8" Vent and Vacuum Fittings and Wall Mounting Bracket

1 each Model A-920 Ejector Assembly including Nozzle, High Back Pressure Check Valve, Spray Diffuser and 3/8" Vacuum Fitting

(OPTIONAL: A-921 Low Pressure Ejector, A-927 Hi/Lo Pressure Ejector, A-950 Dual Check Valve Ejector)

50' VT-1, 3/8" Vent and Vacuum Tubing

10 each G-201 Lead Cylinder Gaskets

1 each Z-296 Rate Valve Tool

1 each Z-297 Vent Line Bug Screen

Approximate Shipping Weight: 17 lbs

CONTENTS: MODEL 226

2 each Model A-826 Switchover Vacuum Regulators with 1/2" Vacuum Fittings

1 each Model 7500-250 Remote Meter Panel with 1/2" Vacuum Fittings (For Wall Mounting)

1 each Model A-300V2 Pressure Relief (Vent) Valve with 1/2" Vent and Vacuum Fittings and Wall Mounting Bracket

1 each Model A-922 Ejector Assembly including Nozzle, High Pressure Check Valve, Spray Diffuser and 1/2" Vacuum Fitting

(OPTIONAL: A-923 Low Pressure Ejector, A-950 Dual Check Valve Ejector)

50' VT-2, 1/2" Vent and Vacuum Tubing

10 each G-201 Lead Cylinder Gaskets

1 each Z-296 Rate Valve Tool

1 each Z-297 Vent Line Bug Screen

Approximate Shipping Weight: 17 lbs

CONTENTS: MODEL 256

2 each Model A-856 Switchover Vacuum Regulators with 5/8" Vacuum Fittings

1 each Model 7500-500 Remote Meter Panel with 5/8" Vacuum Fittings (For Wall Mounting)

1 each Model A-300V3 Pressure Relief (Vent) Valve with 5/8" Vent and Vacuum Fittings and Wall Mounting Bracket

1 each Model A-925 Ejector Assembly including Nozzle, High Pressure Check Valve, Open Diffuser and 5/8" Vacuum Fitting

(OPTIONAL: A-926 Low Pressure Ejector, A-950 Dual Check Valve Ejector)

50' VT-3, 5/8" Vent and Vacuum Tubing

10 each G-201 Lead Cylinder Gaskets

1 each Z-296 Rate Valve Tool

1 each Z-297 Vent Line Bug Screen

Approximate Shipping

possibility and risk of returning cylinders with some remaining gas to the supplier.