SUB CATEGORIES OF Centrifugal Separators

Centrifugal Separator Offerings by Cannon Water Technology

We, at Cannon Water Technology, Inc. have the capability to provide you with various models of centrifugal sand separators for an efficient operation. Here are our offerings:

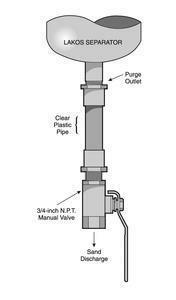

- Lakos ILB Series: This series of centrifugal separators is most commonly used for separating grit and sand from the process liquid system. The Lakos ILB series has the capability to remove around 98% of particles, which are 74 microns or larger. The maximum pressure rating for this series of the separator is 150 psi (10.3 bar). This series is made from A-36 carbon steel.

- Lakos LGS Series: The LGS Series is a high flow solids removal separator. The LGS has a flow range of 225 to 2450 GPM. These solids removal filters are maintenance free and are constructed of A-36 carbon steel.

- Lakos ILS Series: The ILS series of Lakos centrifugal separators require little or no maintenance, since they have no moving parts, which can wear out. This series is made from 316L stainless steel. In addition to this, they do not involve cones, cartridges, or screens, so the time and cost of cleaning or replacing them are eliminated.

- Lakos SandMaster Series: The SandMaster series of centrifugal separators from Lakos are made from 304L stainless steel, which makes them extremely durable. Also, it helps them deliver an optimal operation. These separators are most commonly used in appliances, such as toilet tanks, and hot water heaters. This helps in eliminating the buildup in these appliances. Also, this series of separators helps prevent wear and clogging of sprinkler nozzles.

Benefits of Using Lakos Centrifugal Separators

There are a number of benefits of using centrifugal sand separators for different industrial processes. The following are some major benefits:

- Overall productivity is improved

- Disposal costs of effluent systems are reduced

- Very easy for to operate this equipment

- Facilitates easy cleaning at the end of a production run

Cannon Water Technology, Inc. is one of the most trusted, and well-known supplier of good quality centrifugal separators in the US. You can rely on us, and be rest assured about the quality of products provided by us. Please get in touch with us at the earliest, with your specifications. Our team of expert, skilled, and knowledgeable staff would be happy to help you with the right model of centrifugal separator based on your requirements.

There are some QUESTIONS frequently ASKED by CUSTOMERS. The given below questions are answered by our experts.

-

What is Centrifugal Separator?

A centrifugal separator is a machine that uses centrifugal force to separate components of a mixture based on their density, viscosity and size. It is used for separating liquid particles from solids, removing impurities from liquids.

-

How does a centrifugal separator work?

The basic principle of a centrifugal separator is to spin a mixture at high speeds in a spinning bowl or drum, causing the denser components to move towards the outer edge of the bowl, while the less dense components remain closer to the center.

-

What is the efficiency of centrifugal separator?

The efficiency of a centrifugal separator depends on several factors, including the speed of rotation, the size and shape of the bowl or drum, and the properties of the mixture being separated. It can achieve high separation efficiencies, removing particles or liquids with high precision and accuracy.

-

What are the factors that affect centrifugal separation?

Below factors are affect centrifugal separation.

- Density of both samples and solution.

- Temperature/viscosity.

- Distance of particles displacement.

- Rotation speed.

-

What is the purpose of centrifugal separators?

The purpose of centrifugal separators is to separate components of a mixture based on their density, viscosity, size, or other physical properties, using centrifugal force generated by spinning the mixture at high speeds in a spinning bowl or drum.

-

In which industrial process centrifugal separator is used?

Centrifugal separator is used to separate suspended particles in dairy industry and oil refining industry.

-

What are the advantages of centrifugal separators?

Centrifugation results in an extremely effective separation of both liquid and solid contaminants, which means you can safely use your cutting liquid two to six times longer than with simpler cleaning mechanisms.