SUB CATEGORIES OF Centrifugal Separators

Centrifugal separators are devices that leverage centrifugal force to separate solid particles, such as sand, grit, and debris, from liquids in various industrial processes. These systems are vital in industries such as agriculture, manufacturing, and wastewater treatment, where they remove contaminants to protect equipment and ensure smooth operations.

By eliminating abrasive particles, centrifugal separators extend the lifespan of pumps, valves, and nozzles, reducing maintenance costs and downtime. Their ability to handle high volumes of water makes them indispensable for maintaining water quality in diverse settings. Additionally, these systems promote environmental compliance by facilitating cleaner water discharge. Designed for high-efficiency performance, the centrifugal separator removes up to 98% of particles—like sand—with a specific gravity of 2.6 to 2.8 and sizes as small as 75 microns, as long as a minimum pressure drop of 0.3 bar is maintained across the unit.

How Do Centrifugal Separators Work?

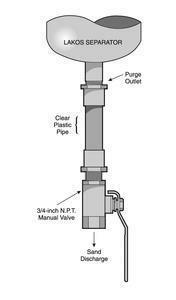

Centrifugal separators operate by spinning a liquid mixture at high speeds within a conical chamber, creating a vortex that separates heavier solids from the liquid. Water enters through a tangential inlet, generating rapid rotational motion. This centrifugal force pushes denser particles, like sand or grit, to the outer edges of the chamber, where they spiral downward into a collection sump.

The cleaner liquid, now free of heavy contaminants, moves toward the center of the vortex and exits through an outlet for further use. The collected solids are periodically flushed out, often through an automatic purge valve, ensuring continuous operation without clogging. This process, known as cyclonic separation, is highly efficient. It removes up to 98% of particles, 74 microns or larger, making it ideal for water solid separator applications.

Types of Centrifugal Filtration Systems Offered by Cannon Water Technology

Centrifugal filtration systems are essential for effective water treatment across various applications. Cannon Water Technology provides a range of high-quality centrifuge filtration systems to meet diverse needs.

- Cyclonic Sand Separator: The LAKOS ILB/ILS series centrifugal separators are a popular choice for removing sand, grit, and other solid particles from water systems using advanced centrifugal force technology. These separators are ideally suited for small system applications, side-stream installations, and individual equipment protection, making them perfect for residential well water systems, irrigation networks, and commercial plumbing applications. Available in both carbon steel and 316L stainless steel construction, these systems provide reliable protection against sediment buildup without the need for screens or filters. Their compact design and low-maintenance operation make them cost-effective solutions for preventing damage to downstream equipment and maintaining optimal water flow.

- Hydrocyclone Solid Removal Separator: The LAKOS LGS series hydrocyclone centrifugal separators handle high-flow applications with flow ranges from 225 to 2450 GPM, delivering industrial-grade solid removal performance for demanding environments. These separators efficiently separate solid particles, sand, and dirt from process water and liquid systems, making them essential for manufacturing facilities, wastewater treatment plants, and heavy industrial applications. Their robust hydrocyclone design creates powerful centrifugal forces that achieve superior separation efficiency while maintaining continuous operation. Built with stainless steel construction for enhanced durability, these separators deliver long-term reliability in corrosive and high-temperature environments.

- Centrifugal Water Well Sand Separators: The SandMaster Plus stainless steel centrifugal separator systems provide comprehensive sand removal solutions for water treatment and filtration applications. These versatile separators are used in a wide range of applications all over the world, from cooling tower systems to process water streams and well water treatment. Their advanced centrifugal action removes bulk contaminants while maintaining consistent water quality and system efficiency. Available in various flow capacities including high-flow models up to 4350 GPM, these separators reduce maintenance costs by preventing clogging and equipment wear in critical water systems.

Advantages of Cyclonic Sand Separator Solutions

Cyclonic sand separators offer significant benefits for water filtration across industries. Their innovative design ensures efficient and cost-effective contaminant removal. Here are some advantages of using centrifuge separators.

- Low Maintenance Requirements: Cyclonic sand separators lack moving parts or filter media, which eliminates the need for frequent maintenance tasks. This design reduces operational interruptions, allowing systems to run smoothly for extended periods. By removing the need for regular filter replacements, cyclonic sand separators lower long-term operational expenses. As a result, businesses save on labor and maintenance costs compared to traditional filtration methods.

- Durable Construction: Constructed from robust materials such as stainless steel, these separators resist corrosion and wear in harsh environments. Their sturdy build ensures reliable performance in demanding industrial settings, such as chemical plants or marine applications. This durability translates to a longer service life and reduced replacement costs.

- Environmental Benefits: Efficient solid removal reduces the reliance on additional water treatment processes, conserving water and chemicals. These separators also minimize waste generation as there are no disposable filters to discard. This supports sustainable practices by minimizing resource consumption and waste. Industries can align with environmental regulations while maintaining operational efficiency.

How to Choose the Right Centrifugal Sand Separator?

Selecting the appropriate centrifugal sand separator ensures optimal performance for specific filtration needs.

- Assess Flow Rate Requirements: Evaluate the water volume your system processes to select a separator with adequate capacity. This ensures efficient operation without compromising performance.

- Consider Particle Size and Type: Analyze the size and density of contaminants in your water source. This helps identify a separator designed to remove those specific solids effectively.

- Evaluate Material Compatibility: Select separators made from durable materials such as stainless steel for corrosive environments. This ensures long-term reliability and performance.

- Check Installation Space: Choose compact designs, such as hydrocyclone separators, for systems with limited space. This allows seamless integration into existing setups.

- Review Maintenance Needs: Opt for separators with automatic purge valves to reduce manual cleaning efforts. This minimizes downtime and enhances operational efficiency.

Applications of Centrifugal Filtration Systems

Here are some application areas of centrifugal filtration systems.

- Irrigation Systems: Cyclonic sand separators remove sand and grit from well water, preventing blockages in sprinkler nozzles. This ensures consistent water flow for agricultural irrigation needs.

- Industrial Manufacturing: These systems eliminate debris from process water, protecting pumps and heat exchangers. This reduces equipment wear in facilities such as food processing plants.

- Residential Water Treatment: Water solid separators prevent sediment buildup in household appliances such as water heaters. This enhances water quality and extends equipment lifespan.

- Wastewater Treatment: Centrifugal separators remove sludge and solids from wastewater, aiding regulatory compliance. They also enable water reuse in industrial facilities.

- Cooling Towers: By removing particulates from recirculating water, these systems prevent fouling in cooling towers. This maintains operational efficiency and reduces maintenance costs.

- Pharmaceutical and Food Industries: Centrifuge filtration systems ensure high water purity for production processes. This is critical for meeting strict industry quality standards.

Centrifugal Separator Offerings by Cannon Water Technology

We, at Cannon Water Technology, Inc. have the capability to provide you with various models of centrifugal sand separators for an efficient operation. Here are our offerings:

- Lakos ILB Series: This series of centrifugal separators is most commonly used for separating grit and sand from the process liquid system. The Lakos ILB series has the capability to remove around 98% of particles, which are 74 microns or larger. The maximum pressure rating for this series of the separator is 150 psi (10.3 bar). This series is made from A-36 carbon steel.

- Lakos LGS Series: The LGS Series is a high flow solids removal separator. The LGS has a flow range of 225 to 2450 GPM. These solids removal filters are maintenance free and are constructed of A-36 carbon steel.

- Lakos ILS Series: The ILS series of Lakos centrifugal separators require little or no maintenance, since they have no moving parts, which can wear out. This series is made from 316L stainless steel. In addition to this, they do not involve cones, cartridges, or screens, so the time and cost of cleaning or replacing them are eliminated.

- Lakos SandMaster Series: The SandMaster series of centrifugal separators from Lakos are made from 304L stainless steel, which makes them extremely durable. Also, it helps them deliver an optimal operation. These separators are most commonly used in appliances, such as toilet tanks, and hot water heaters. This helps in eliminating the buildup in these appliances. Also, this series of separators helps prevent wear and clogging of sprinkler nozzles.

Benefits of Using Lakos Centrifugal Separators

There are a number of benefits of using centrifugal sand separators for different industrial processes. The following are some major benefits:

- Overall productivity is improved

- Disposal costs of effluent systems are reduced

- Very easy for to operate this equipment

- Facilitates easy cleaning at the end of a production run

Cannon Water Technology, Inc. is one of the most trusted, and well-known supplier of good quality centrifugal separators in the US. You can rely on us, and be rest assured about the quality of products provided by us. Please get in touch with us at the earliest, with your specifications. Our team of expert, skilled, and knowledgeable staff would be happy to help you with the right model based on your requirements.

There are some QUESTIONS frequently ASKED by CUSTOMERS. The given below questions are answered by our experts.

-

What is Centrifugal Separator?

A centrifugal separator is a machine that uses centrifugal force to separate components of a mixture based on their density, viscosity and size. It is used for separating liquid particles from solids, removing impurities from liquids.

-

How does a centrifugal separator work?

The basic principle of a centrifugal separator is to spin a mixture at high speeds in a spinning bowl or drum, causing the denser components to move towards the outer edge of the bowl, while the less dense components remain closer to the center.

-

What is the efficiency of centrifugal separator?

The efficiency of a centrifugal separator depends on several factors, including the speed of rotation, the size and shape of the bowl or drum, and the properties of the mixture being separated. It can achieve high separation efficiencies, removing particles or liquids with high precision and accuracy.

-

What are the factors that affect centrifugal separation?

Below factors are affect centrifugal separation.

- Density of both samples and solution.

- Temperature/viscosity.

- Distance of particles displacement.

- Rotation speed.

-

What is the purpose of centrifugal separators?

It is used for separate components of a mixture based on their density, viscosity, size, or other physical properties, using centrifugal force generated by spinning the mixture at high speeds in a spinning bowl or drum.

-

In which industrial process centrifugal separator is used?

Centrifugal separator is used to separate suspended particles in dairy industry and oil refining industry.

-

What are the advantages of centrifugal separators?

Centrifugation results in an extremely effective separation of both liquid and solid contaminants, which means you can safely use your cutting liquid two to six times longer than with simpler cleaning mechanisms.