SUB CATEGORIES OF Pulsafeeder Pumps

Features of Pulsafeeder Metering Pumps

There are a number of reasons for the popularity of Pulsafeeder chemical pumps. First, the pumps from the brand known for its accuracy and precision. This makes it ideal for various applications, from medical to industrial. Additionally, the pumps are affordable, making them a great option for a variety of budgets. Other notable features that add to their popularity include;

- These pumps are extremely easy to operate and maintain.

- The metering pumps are deigned to dispense the same amount of liquid each time they are used.

- Peristaltic chemical metering pumps are made from durable components and are known for robust construction.

- These pumps are designed for long-term use in demanding industrial applications even with constant interaction with chemicals, strong acids, salt water, and organic solvents.

- They are not affected by changes in temperature. This makes them ideal for applications where the temperature of the fluid being pumped may vary.

- Equipped with quad check valve system, stroke length control and sealed gear train, these pumps guarantee reliable performance and accurate metering of chemicals.

- Treated with a special lubricant, their motor and gear shaft demand minimal maintenance.

- They guarantee excellent chemical resistance, thanks to their innovative construction using injection-moulded pump head and a housing.

- Pulsafeeder's metering pumps are constructed with the highest quality stainless steel fasteners to ensure durability and longevity.

- Pulsafeeder metering pumps can be wall mounted. This is a great way to save space, and it also gives you the option to put the pump exactly where you need it. Wall mounting also makes it easier to service the pump, and it can help to protect the pump from damage.

- Pulsafeeder's line of metering pumps are perfect for a variety of applications, including those that require water resistance.

- Pulsafeeder metering pumps have only a few moving parts, adding to their easy maintainability.

- Pulsafeeder peristaltic pumps are also equipped with the following features:

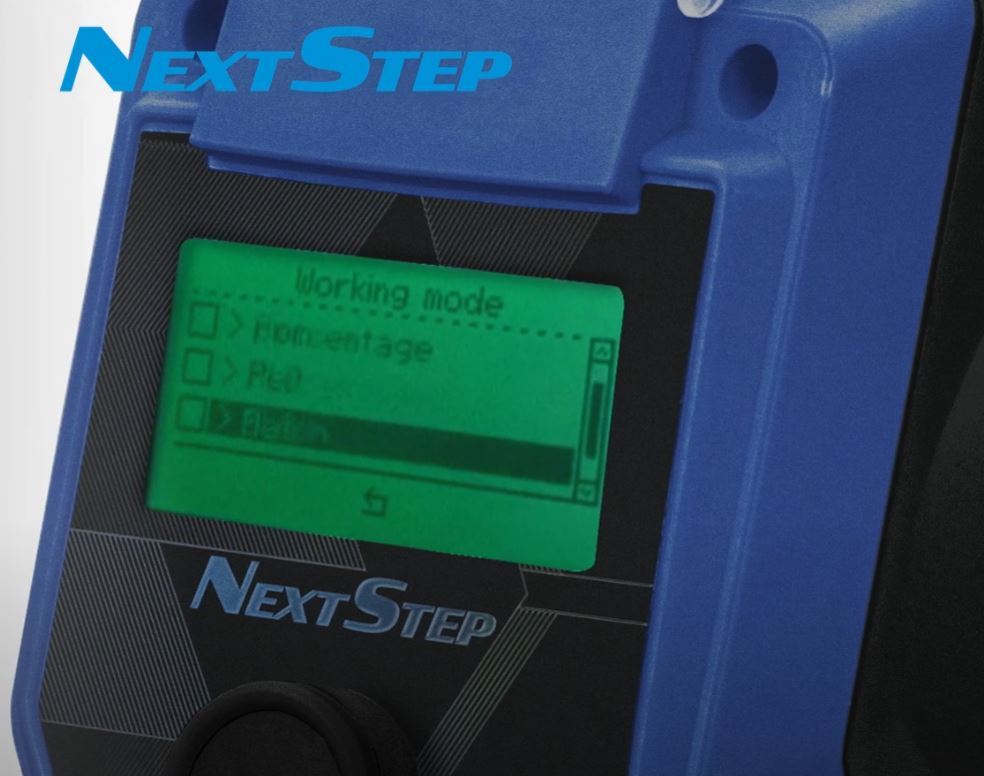

- Timer controls and an intuitive interface

- Rugged gear train

- Circuit protection against voltage and current upsets

- Solenoid protection by thermal overload with auto-reset

- Durable leak-free bleed valve assembly

- Internally dampened to reduce noise

Peristaltic metering pumps from Pulsafeeder offer many advantages over other types of pumps, including their ability to run dry without damage, their self-priming nature, and their accuracy and repeatability.

How Does Peristaltic Chemical Metering Pumps Work?

Peristaltic chemical metering pumps work by using a peristaltic action to move the fluid through the pump. The peristaltic action is created by a rotating wheel or gears that press against a flexible tubing. As the wheel or gears rotate, they compress the tubing and push the fluid through the pump.

Factors to Consider When Choosing the Pulsafeeder Peristaltic Pump

When it comes to buying peristaltic metering pumps, there are a few factors you should consider before making your selection. This includes the following:

- Accuracy: Pumps with high levels of accuracy can provide significant advantages in many applications. In some cases, a higher level of accuracy may be necessary to meet specific regulatory requirements. In other cases, extreme accuracy may simply be desired in order to improve the overall performance of the application.

- Pumping Requirements: Next, you will need to consider the specific pumping requirements of the application. This includes factors such as discharge pressure, and chemical compatibility.

- Flow Rate: Peristaltic pumps work by moving a flexible tube through a series of rollers, which presses the tube and forces fluid through it. The flow rate of a peristaltic pump is determined by the size of the pump and the speed at which the rollers move.

- Type of Fluid: Peristaltic pumps are well suited for various fluids, including acids, alkalis, and corrosives; however, some fluids are more difficult to pump than others. For example, fluids with high viscosity, solids, or particulates can be difficult to pump and may require special considerations.

- Corrosion Resistance: When selecting a peristaltic metering pump for your application, it is important to consider the corrosion resistance of the materials that the pump is made from. The pump's housing and internal components must be able to withstand the chemicals that will be pumped by the device.

- Safety: When selecting a peristaltic metering pump, look for a pump that is certified by a prominent safety standard. Peristaltic metering pumps can be dangerous if they are not used properly. They can leak and cause fires. They can also explode if they are not used correctly. So, it is important to select a pump that is safe for your application. Make sure the pump you select has all the safety features you need for your application.

- Maintenance: Consideration of the required maintenance procedures of a peristaltic metering pump is a significant factor in the selection process. These pumps are often used in mission critical applications where downtime is not an option.

Applications

Pulsafeeder’s pumps are an ideal choice for metering chemicals in industrial facilities. Some common applications include:

- Manufacturing: Pulsafeeder chemical pumps are used for metering sodium silicate in paper and pulp production; ethylene glycols when manufacturing textiles, plastics, adhesives, and latex; methanol during MTBL production for petrol refining and solvent production.

- PH Control: The pumps are used for metering sulfuric acid, caustic soda, sodium bisulfite, and lime slurries for pH control in water.

- Disinfection: Pulsafeeder peristaltic pumps are used for metering sodium and calcium hypochlorite, hydrogen peroxide, bromine, copper sulfate, and ammonium sulfate.

- Heavy Metal Removal: These pumps are used for metering potassium permanganate, phosphate, and hydrochloric acid for metal removal.

Cannon Water Technology is proud to offer a variety of Pulsafeeder dosing pumps to meet your needs. We carry a wide range of models to suit any application, and our team is always available to help you select the right pump for your needs. Contact us today to learn more about our products and how we can help you select the right pump from the Pulsafeeder brand for your application.